Technology

Manufacturing Processes

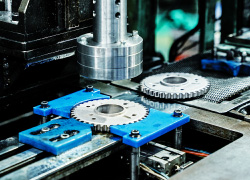

Powder metallurgy is a method for manufacturing metallic parts by mixing and compacting metallic powders and then using heat to bind them together. The processes of products completed and delivered to customers are introduced here.

Mixing and Blending

Compacting

Sintering

Sizing

Machining

Post-treatment

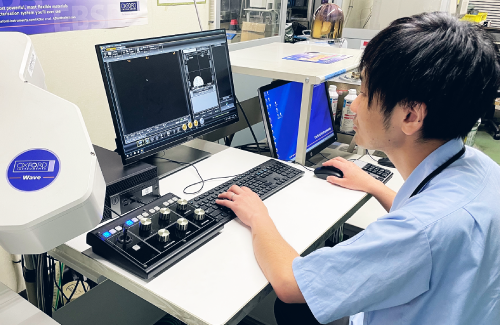

Inspection

In addition, the appearance of products is confirmed if there is no defect.

Shipment

Benefits of Powder Metallurgy

1. Economic efficiency

Near net shape materials can be manufactured using high-precision die assemblies for products with complicated shapes, thus raw material and machining costs can be reduced.

2. High productivity

Continuous compacting is possible using die assemblies; therefore, mass production and superior yield can be achieved.

3. Uniqueness

Products are manufactured from metallic powders; therefore, changing their compositions imparts mechanical properties that meet customer demands to products. In addition, controlling the metallographic structures according to manufacturing conditions makes it possible to respond to different applications.

Comparison with Other Manufacturing Methods

| Item | Part manufacturing method | ||||||

|---|---|---|---|---|---|---|---|

| Powder Metallurgy | Forging | Casting | Stamping | Injection molding | Cutting and polishing | ||

| Shape | planar complexity | ◎ | ○ | ○ | ◎ | ◎ | ◎ |

| steric complexity | ◎ | ○ | ◎ | – | – | ◎ | |

| Composite and integrated | – | – | – | ◎ | ◎ | – | |

| Productivity | 100 pcs or less | – | – | ◎ | – | – | ◎ |

| 3,500 pcs | ◎ | ◎ | ○ | ○ | ○ | – | |

| 5,000 pcs or more | ◎ | ○ | – | ◎ | ◎ | – | |

| Uniqueness | Porosity | ◎ | – | ○ | – | – | – |

| Specialized composition and metallographic structure | ◎ | ○ | ○ | – | – | – | |

| Precision | Several hundreds of millimeters or more | ○ | ○ | ◎ | ○ | ○ | ○ |

| Several tens of millimeters | ◎ | ◎ | ○ | ○ | ◎ | ◎ | |

| Several millimeters or less | ◎ | ○ | – | ◎ | ◎ | ◎ | |

| Weight | Several hundreds of grams or more | ○ | ○ | ◎ | ○ | – | ○ |

| Several tens of grams | ◎ | ◎ | – | ◎ | ◎ | ◎ | |

| Several grams or less | ◎ | – | – | ◎ | ◎ | ◎ | |

| Material | High melting point and high reactivity | ◎ | ○ | ○ | – | – | – |

| Amorphous and rapidly solidified | ◎ | ○ | ◎ | – | – | – | |

| Mechanical properties | Strength | ○ | ◎ | ○ | ○ | – | ◎ |

| Toughness | ○ | ◎ | – | ○ | ○ | ○ | |

| Hardness | ○ | ○ | ○ | ○ | ○ | ○ | |

| Wear resistance | ○ | ○ | ○ | – | – | – | |

◎:Very characteristic advantage

○:Advantage

Product Development

Diamet has developed, manufactured, and sold sinter metal components consistently since its foundation. Powder metallurgy is a simple manufacturing method where powdered metals are mixed, compacted with a press, and sintered to finish.

However, the compacting pressure and sintering temperature need to be changed according to the types and amounts of powders to be mixed, and our technologies are fully used in each process. In addition, manufactured materials and products have characteristics suitable for respective purposes and applications.

A wide variety of metals can be mixed, and we adjust the powder formulations for the respective products.

The Development Department focuses on a wide variety of themes ranging from the selection of raw powder materials to new technologies and manufacturing methods and strives for development that realizes the required performances and functions to meet customer demands.